Protective Coatings for Marine & Off-shore Structures

The challenging needs of the offshore industry have been a focus for Afzir Company for many years. These demanding requirements are particularly well met with our excellent protective coatings range featuring outstanding tank linings, zinc-rich primers, general-purpose epoxy primers and durable finishes which, combined with our hydrocarbon PFP offering, give us a world-class package of fit-for-purpose solutions.

- Drillships

- FPSO

- Rigs & platforms

- Subsea

- Case Studies

- Global Protective Products

- NORSOK M-501

With world-class heavy-duty coatings, wide-ranging expertise and dedicated staff, PPG is the natural partner to safeguard offshore assets. Our coatings provide efficient application and are designed to support our customers and improve their productivity.

Structural Steel

Our products are designed to withstand aggressive environments to protect structural steel components used in offshore platforms, structures, drill rigs and FPSOs (Floating production storage and offloading units). In addition to outstanding protection, our tough finishes give excellent aesthetics in a wide range of colors and have been designed to work well in fabrication environments where ease of use, drying time and productivity are critically important.

Storage Facilities

We are the market leader in storage tank coatings, offering protection against corrosion to maintain tank investments in both solvent-borne and solvent-free formulations. Our chemical-resistant linings avoid product contamination for a wide range of chemicals, crude oil, potable water and refined petroleum products.

Floors and Decks

Durability, application flexibility, chemical resistance and excellent non-skid properties characterize our coatings for these areas.

Subsea equipment

Subsea operational conditions present unique challenges for protective coatings that are subjected to near-freezing subsea external temperatures and extremely hot production fluid internal temperatures. Our subsea coatings provide the most advanced protection available today, have been independently proven to protect subsea equipment, and are compatible with cathodic protection at elevated temperatures.

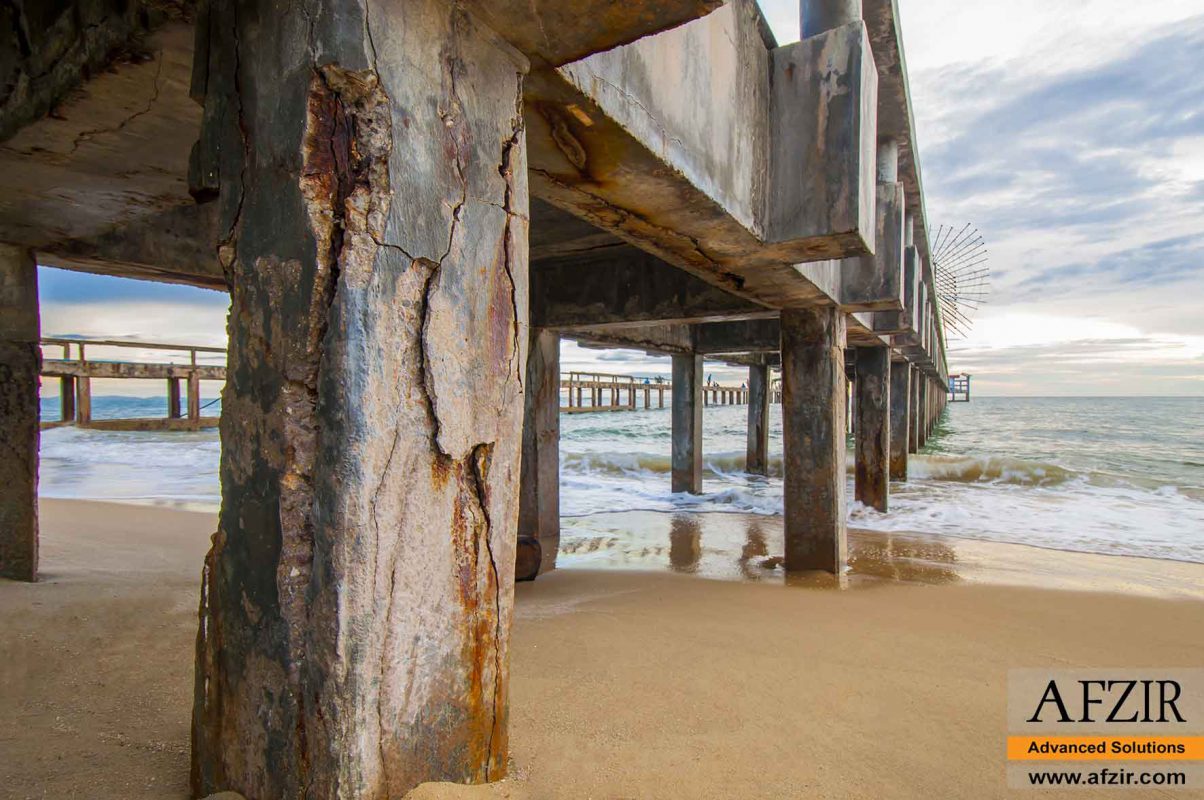

Splash and tidal zones

Splash and tidal zones can be particularly aggressive areas for protective coatings due to the constant abrasion associated with wave and tidal surges, periodic impact events from floating watercraft and debris and the constant wet-dry cycling combined with UV exposure and extreme salinity. Our splash zone protective coatings are specifically formulated to protect steel structures in these demanding and abrasive conditions.

High-temperature applications

We offer a range of heat-resistant, high-performance coatings that meet the high-temperature requirements of the offshore industry. These coatings protect steel surfaces, pipes and process equipment from the effect of extended elevated temperature and thermal cycling.

Passive Fire Protection

The intumescent coating provides passive fire protection (PFP) material, gives proven protection against the most aggressive types of hydrocarbon fires including jet fires. Its unique flexibility provides protection against mechanical abuse and can help ensure intact fire protection after explosive incidents that often coincide with hydrocarbon fires.